Ambient Temperature Correction Factor

Are you aware of the importance of ambient temperature correction factor in the electrical industry? This factor plays a significant role in ensuring the safe and efficient operation of electrical systems. In this post, we'll discuss ambient temperature correction factor in detail and why it is important to consider in your electrical projects.

Pain Points Related to Ambient Temperature Correction Factor

If you're working in the electrical industry, you may have encountered situations where you are unsure about how to calculate the appropriate cable size for a project, or how to determine the maximum load that an electrical device or equipment can handle. These questions can be daunting, especially when the ambient temperature is taken into account.

What is the Target of Ambient Temperature Correction Factor?

Ambient temperature correction factor is necessary because electrical equipment generates heat, and this heat can be affected by the surrounding temperature. When the temperature rises above a certain level, the current-carrying capacity of the cable or conductor is reduced. This reduction can result in safety hazards and equipment failures. Ambient temperature correction factor is a method used to adjust the current-carrying capacity of cables and electrical devices based on the surrounding temperature.

Summary of the Main Points

In summary, ambient temperature correction factor is an important concept to consider when working on electrical projects. It ensures the safe and efficient operation of electrical systems by adjusting the current-carrying capacity of cables and equipment based on the surrounding temperature. This factor addresses the heat generated by the electrical equipment and the effect it has on the cable's current-carrying capacity.

The Importance of Ambient Temperature Correction Factor

The target of ambient temperature correction factor is to ensure that electrical equipment runs efficiently and safely in different temperature conditions. With the correct ambient temperature correction factor, the circuit or cable can carry the required load while maintaining safe operating temperatures. However, if the temperature is too high, the insulation or conductor may degrade, resulting in equipment failure or fire.

Let's say you are working on a commercial building project where the electrical equipment is likely to generate more heat due to increased usage. In this case, you need to ensure that the cables and devices are installed appropriately, considering the surrounding temperature. Failing to account for the ambient temperature and apply the correct correction factor could lead to electrical hazards that could cause significant harm.

Ambient Temperature Correction Factor and Cable Selection

When selecting cables for electrical projects, ambient temperature correction factor plays a crucial role. The temperature correction factor is used to adjust the maximum load for cables operating in a higher-than-standard temperature area. It is essential to understand how to calculate the correction factor for a given cable, which involves knowing the operating temperature and rating of the cable.

For example, suppose you are installing a cable in an area where the ambient temperature is 45 °C. If the maximum current-carrying capacity of the cable at standard temperature is 100 amps, applying the appropriate correction factor can enable the cable to carry the appropriate current without exceeding the maximum temperature limit of the conductor or insulation.

Image source: https://i.stack.imgur.com/HtfoQ.png

The Role of Ambient Temperature Correction Factor in Electrical Safety

Electrical safety is the primary reason why ambient temperature correction factor is vital in the industry. Electrical equipment generates heat, and the surrounding temperature can increase this heat, putting the equipment and anyone in the vicinity at risk. By accounting for the ambient temperature, we can ensure that the equipment is operating safely and efficiently within its capacity.

Benefits of Ambient Temperature Correction Factor

Some benefits of using ambient temperature correction factor in electrical projects include:

- Increased accuracy in maximum current-carrying capacity calculations

- Ensures safe operation of electrical equipment in different temperature conditions

- Reduces the risk of electrical hazards, such as fires and equipment failures

- Improves the lifespan of the electrical equipment

How to Calculate Ambient Temperature Correction Factor?

To calculate the ambient temperature correction factor, you need to consider the maximum operating temperature of the equipment or cable and the standard temperature rating. This can help to determine the correction factor that needs to be applied to ensure that the equipment is operating under safe conditions.

Question and Answer Section

Q: Why is it essential to consider ambient temperature correction factor in electrical projects?

A: Ambient temperature correction factor ensures that electrical devices operate safely and efficiently in different temperature conditions. By accounting for the surrounding temperature, we can avoid electrical hazards, such as fires and equipment failures.

Q: What are some advantages of applying ambient temperature correction factor?

A: Some advantages of using ambient temperature correction factor include increased accuracy in maximum current-carrying capacity calculations, safe operation of electrical equipment in different temperature conditions, reduced risk of electrical hazards, such as fires and equipment failures, and improved lifespan of electrical equipment.

Q: How does ambient temperature affect electrical equipment?

A: Electrical equipment generates heat, and the surrounding temperature can increase this heat, putting the equipment and anyone in the vicinity at risk. When the temperature rises above a certain level, the current-carrying capacity of the cable or conductor is reduced. This reduction can result in safety hazards and equipment failures.

Q: What factors should be considered when calculating the ambient temperature correction factor?

A: The maximum operating temperature of the equipment or cable and the standard temperature rating are factors that need to be considered when calculating the ambient temperature correction factor.

Conclusion

Ambient temperature correction factor is a crucial aspect to consider when working on electrical projects. It ensures that the equipment operates safely and efficiently in different temperature conditions, avoiding electrical hazards. By accounting for the surrounding temperature, you can calculate the appropriate cable size or maximum load that an electrical device or equipment can handle, making it an essential concept in the electrical industry.

Gallery

Ambient Temperature Correction | Download Table

Photo Credit by: bing.com / ambient demography participant surveyed proximate microalgae analyses

Electrical - How Should I Apply Ambient Air Temperature Ampacity

Photo Credit by: bing.com / temperature ampacity ambient air nec correction factors electrical table 310 tables apply should wire when exact unknown determine stack

The Importance Of "Ambient Temperature Based Correction Factor," On The

Photo Credit by: bing.com /

Modern Commercial Wiring, 7th Edition Page 94

Photo Credit by: bing.com /

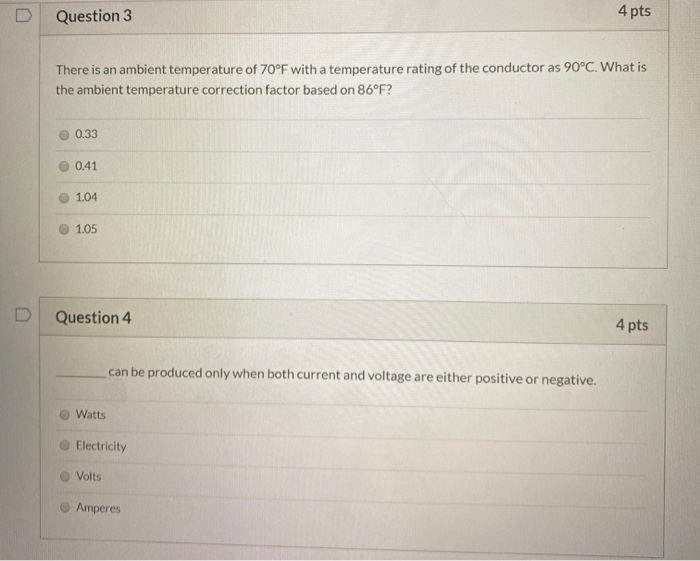

Solved Question 3 4 Pts There Is An Ambient Temperature Of | Chegg.com

Photo Credit by: bing.com /

0 Response to "Ambient Temperature Correction Factor"

Posting Komentar