Part Start Winding

A motor is an essential component in many industries. It converts electrical energy into rotational energy, making various processes more efficient. However, when starting a motor, there are certain challenges, and one of them is called part start winding.

Pain Points of Part Start Winding

Part start winding is a starting method for induction motors, frequently used in medium to large size motors. The traditional method for starting motors is a direct online starter, which can cause voltage fluctuations and current spikes, leading to machinery breakdown and power supply disturbances. Part start winding is an alternative method that provides automation control and a smoother start for the motor. However, it still needs proper maintenance and monitoring for optimal performance.

Target of Part Start Winding

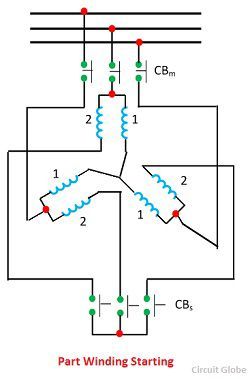

The function of part start winding is to reduce the starting current of induction motors. The method uses two sets of stator windings, one with a higher number of turns and a lower resistance value, and the other with a lower number of turns and a higher resistance value. During the initial stage of the motor's operation, the starting current flows only through the high-resistant winding. Once the motor reaches a specific speed, the low-resistant winding is added in parallel to supply more current and increase the torque necessary to accelerate the load.

Main Points of Part Start Winding

Part start winding is an alternative method of starting induction motors, which reduces the starting current and provides smoother motor operation. The method uses two sets of stator windings, a high-resistant winding and a low-resistant winding, to gradually increase the motor's torque and acceleration. Proper maintenance and monitoring are still required for maximum performance.

Personal Experience with Part Start Winding

My experience with part start winding was in a manufacturing company that used a large induction motor for its production process. Initially, we used a direct online starter, but it caused voltage fluctuations and breakdowns that halted the operation frequently. We then switched to part start winding, which provided a better automation process and smoother operation for the motor. Since then, we have had no machinery breakdowns or power supply disturbances, and we save on energy costs as well.

Advantages of Part Start Winding

The advantages of using part start winding are that it reduces the starting current, provides smoother motor operation, and avoids voltage fluctuation and current spikes which cause machinery breakdowns, leading to lower maintenance costs. Furthermore, since it is an automated process, it saves time and resources while enhancing the motor's efficiency.

Working Principles of Part Start Winding

Part start winding works based on the principle of impedance mismatch. The high-resistant winding has more impedance compared to the low-resistant winding, and as a result, it reduces the flow of current during starting. As the motor gains speed, the induced voltage increases, causing the low-resistant winding to add in parallel and supply more current to increase the torque necessary to accelerate the load. This process provides a gradual start for the motor, reducing the stresses on the mechanical parts and extending the motor's lifespan.

Maintaining Part Start Winding Motors

Part start winding motors require proper maintenance to ensure optimal performance. The insulation resistance of the windings should be checked regularly, and if it drops beyond a specific limit, the windings should be rewound. The contact points of the switch should be cleaned and lubricated to ensure a smooth transfer of current. Furthermore, if the motor operates in a harsh environment, it should be cleaned and inspected regularly to avoid dust and moisture accumulation, which can cause leakage currents and insulation breakdowns.

Question and Answer

Q: What is the difference between part start winding and direct online starters?

A: Part start winding provides smoother motor operation and reduces starting current compared to direct online starters. Moreover, it avoids voltage fluctuations and current spikes that can cause machinery breakdowns.

Q: Are part start winding motors energy-efficient?

A: Yes, part start winding motors are energy-efficient as they reduce the starting current and provide a gradual start for the motor, which avoids mechanical stresses and extends the motor's lifespan.

Q: What are the maintenance requirements for part start winding motors?

A: Part start winding motors require regular maintenance, including checking the insulation resistance of the windings, cleaning and lubricating the contact points of the switch, and inspecting the motor for dust and moisture accumulation.

Q: What industries typically use part start winding motors?

A: Part start winding motors are frequently used in medium to large size motors in industries such as manufacturing, oil and gas, HVAC, and water treatment because they provide smoother motor operation and reduce starting current.

Conclusion

Part start winding is an alternative method for starting induction motors that provides a smoother start, reduces starting current, and avoids voltage fluctuations and current spikes that can cause machinery breakdowns. It is a cost-effective and efficient automation control process that requires proper maintenance and monitoring for optimal performance.

Gallery

What Is Induction Motor Drive? Explanation & Starting Methods - Circuit

Photo Credit by: bing.com / winding part starting motor starter induction resistance rotor

Part Winding

Photo Credit by: bing.com / winding delta wye contactors 1m

Part Winding

Photo Credit by: bing.com / winding

How A Part-Winding Start Motor Works - Ed's Supply Co.

Photo Credit by: bing.com / winding

Part Winding Starters

Photo Credit by: bing.com / winding starters

0 Response to "Part Start Winding"

Posting Komentar